Depositors 16 SD

The CMC-America 16 SD Depositor is a narrow body continuous depositor designed to form and deliver wire-cut dough pieces of a better weight uniformity onto standard, impression or muffin pans. While the production capacity of the 16 SD will vary based on size, shape/design and dough texture, it will prepare up 10,000 pieces per hour. Whether your cookies are headed right to the oven — or into the freezer – the CMC-America 16 SD is ready for the task.

Download Brochure

Sanitary, Safe and Easy to Clean & Maintain

The 16 SD’s dough hopper, feed roll shafts and table top are stainless steel, while the dough feed rolls and filler block dies are of sanitary aluminum and UMHW polyurethane. Safety guards keep moving parts totally enclosed. These parts are easily removable for cleaning – no tools necessary – and are dishwasher safe. This means you can quickly go from recipe to recipe without the need for removing mechanical drive components. The machine occupies a floor area of 66” x 32” and moves on 4” casters for easy storage when not in use.

Most Every Cookie Shape You Can Think Of…. and More

From the unique way we place our agitators to the way we control dough temperatures, our roller bar technology leads to full absorption for fast development of a uniform dough cell structure and gluten network. Yes. This leads to faster mixing times. But, equally important, the quality of the dough is expertly maintained for each batch.

Variable Speed Control Means It Works as Fast as you Do…

and Grows as Big as you Grow

Each and every CMC-America depositor has variable speed control, meaning that you are in total charge of production speed and volume. Both extrusion rate and pan feed are adjustable. This is very important for the baker who runs multiple recipes and multiple products (i.e. scones, cookies, etc.) each day. It’s even more important when you grow and need to produce in even larger quantities. That’s why we offer dough hoppers in various sizes: 30 QT, 45 QT & 60 QT.

Want to download or print more information about our Depositors 16SD?

Click the button below to open the .pdf document. You can then download and print the detailed information!

Open Detailed Information Sheet

Depositor 24 SD

The CMC-America 24 SD Depositor is a wide body, continuous extrusion machine for bakers who want added volume capacity without added man hours. While the production capacity of the 24 SD will vary based on cookie size, cookie shape/design and dough texture, the 24 SD will prepare up to 15,000 pieces per hour. Also perfect for heavy muffin doughs, scones, biscuits and other recipes, the 24 SD is easy to operate and maintain. The continuous feed pan guide is adjustable for 26” wide pans. ‘Go Wide’ with the 24 SD and enjoy the benefits of CMC- America’s expertise in continuous dough extrusion.

Download Brochure

Higher Production Volumes…. Same Ease of Use

Whether you are producing cookies, brownies, heavy-dough muffins, scones or other recipes, you will see increased production with reliable weight conformity without increased man hour costs, vs. smaller depositing machines. What’s more, all food area parts are easily removable for quick cleaning and replacement and its sturdy 4” casters make the 24 SD easily movable.

Safe, Sanitary with Numerous Applications

Made of stainless steel, no-rust aluminum and UHMW polyurethane, the 24 SD ensures sanitation throughout the product zone. Safety guards keep all moving parts enclosed, and all moving parts are no-tool removable and dishwasher safe for quick cleaning and recipe change-out. Filler block dies are available in every conceivable shape, holiday and recipe. We will make custom dies for you as needed.

Variable Speed Control

Each and every CMC-America depositor has variable speed control, meaning that you are in total charge of production speed and volume. Both extrusion speed and pan feed are adjustable. This is very important for the baker who runs multiple recipes and multiple products (i.e. scones, cookies, etc.) each day. Its even more important when you grow and need to produce in even larger quantities. The 24 SD offers a standard 45 qt. hopper. Larger sizes are available.

Want to download or print more information about our Depositor 24SD?

Click the button below to open the .pdf document. You can then download and print the detailed information!

Open Detailed Information Sheet

Depositor 65 S

Bakers can make money on cookies if they have a reliable, scalable ‘partner’ that can significantly increase output while significantly decreasing time and manpower. But, cookies aren’t the only thing a baker bakes. When the batches are run, the whole cookie operation needs to be moved to create space for other items. We designed the 65 S with the retail baker in mind. It’s a flexible, easy to use piece of equipment that will provide you with years of dependable, customer-pleasing operation.

Download Brochure

Run as Much Dough as you Need. Change Recipes Quickly

Cookies come in all shapes and sizes and some doughs behave differently than others. Nevertheless, a standard sugar cookie dough can run through the 65 S at up to 10,000 pieces per hour if you require. More importantly, all moving parts, and the dough hopper, are no-tool removable and dishwasher safe for quick recipe change outs. Many 65 S customers run a variety of doughs (cookies, scones, etc.) through this unit.

Sanitary. Reliable. Convenient. Safe.

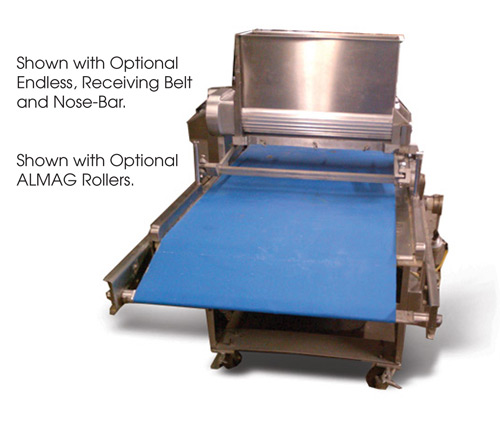

From its stainless steel hopper, table top and feed roll shaft to its UHMW polyurethane feed rolls and “ALMAG” aluminum alloy dies, die holder and cutter fingers, the CMC-America 65 S is designed and manufactured for sanitary operation. Safety guards protect all moving parts. Operation set up and use is intuitive. Mounted on 4” sanitary casters, the 65 S can be easily moved out of the way when cookie production is over.

Variable Speed Control Means the 65 S can Truly Grow with your Business

Each and every CMC-America depositor has variable speed control, meaning that you are in total charge of production speed and volume. Both extrusion speed and pan feed are adjustable.

Want to download or print more information about our Depositor 65S?

Click the button below to open the .pdf document. You can then download and print the detailed information!

Open Detailed Information Sheet

Depositor 85 S

We like to call the 85 S THE Automatic Depositor. With its wider footprint, rollers designed to extrude doughs of a wide range of consistencies and standard 45 qt. stainless steel hopper, the 85 S is designed for the bakery operation that needs larger batch runs with no fuss and with CMC-America’s well known ease-of-use. If your bakery needs to able to boost production from time to time — and to do so across a variety of recipes – without boosting manpower or man-hours, the 85 S is for you.

Download Brochure

Up-To 15,000 Pieces Per Hour. Minutes to Change-Out Recipes. Years of Reliable Safety

While production volume depends upon recipe, dough consistency and the shape and size of your product, the 85 S is designed to produce a large volume, up to 15,000 pieces per hour, when used on most doughs. But, when the time comes to change out recipes, all moving parts are no-tool removable and dishwasher safe. In-use, safety guards keep production running and safe production a priority.

Works in Thick and Thin

The 85 S can tackle all standard cookie doughs as well as dough for: scones, biscuits, biscotti, brownies, gourmet cookies and heavy muffins. Product spacing, dough piece weights and pan guides are all easily adjustable and runs on a 1 HP motor. The unit is mounted on sanitary casters for easy movement throughout your bakery.

Variable Speed Control

Each and every CMC-America depositor has variable speed control, meaning that you are in total charge of production speed and volume. Both extrusion speed and pan feed are adjustable. This is very important for the baker who runs multiple recipes and multiple products (i.e. scones, cookies, etc.) each day. It’s even more important when you grow and need to produce in even larger quantities.

Want to download or print more information about our Depositor 85S?

Click the button below to open the .pdf document. You can then download and print the detailed information!

Open Detailed Information Sheet

Depositor XRS Series

For dough depositing on an Industrial Scale, CMC-America proudly manufactures the XRS series. Custom manufactured, with depositor head widths of up to 1.2 meters, the XRS is specifically for large-scale production. It can also be applied to frozen dough or cluster pack depositing across a wide variety of recipes. Our smallest XRS can move from 1 tonne to 2 tonnes of dough per hour. The unit forms, weighs and places – in a uniform array – dough pieces onto paper for transfer into freezing for subsequent layered packaging or right onto baking bands for instant production.

Download Brochure

Custom Manufactured for Serious, High-Volume Operations

We have designed and delivered XRS units in three widths: 24”/630mm, 32”/800mm, 39”/1 M and 47”/1.2M. Wire cut dough pieces are placed directly onto oven bands, or waxed paper, ready for baking, packaging or freezing. The unit is perfect for Cookies, Scones, Biscotti, Brownies, and Biscuits. Call us to discuss your needs.

Sanitary, Safe & Easy to Use with Low Cost of Ownership

We designed the latest sanitary standards into the XRS with: stainless steel 50 qt. hopper, conveyor bed plates, shafting and stand offs and Aluminum feed rolls, filler block dies, die holder and zone components. The XRS is BISSC approved and USDA accepted. Sanitary wash down design elements are central to the machine’s design as all moving parts are no-tool removable and dishwasher-safe. Pressure grease fittings are permanently sealed and composite ball bearings are included. Lubrication and maintenance are simple and safe. The XRS conforms to OSHA guarding, ANSI Z50 and is UL listed.

Total Control

The XRS is touch screen controlled with Baldor ‘Smart Move’ 2 axis control teamed with precise control Servo drives. Optimal settings for production runs can be saved and stored as programs for easy repeat use. Both the conveyor belt and the feed rolls operate on variable speed drive. The XRS boasts exclusive, aggressive feed rolls to provide consistent dough feed for a wide variety of products.

Want to download or print more information about our Depositor XRS?

Click the button below to open the .pdf document. You can then download and print the detailed information!

Open Detailed Information Sheet